A terminal block connector can be a useful item when you are wiring an electrical job. It’s an effective way to combine wires safely and neatly. You see terminal strips more often in a factory-type environment that must connect many wires.

To put a terminal strip on correctly, the ends of the wires need to have their insulation removed first. Then, insert the wires into the appropriate places on the strip. Once all of the wires are hooked up, screw them down tight. Prior to powering up, it is crucial to verify that the connections are tight.

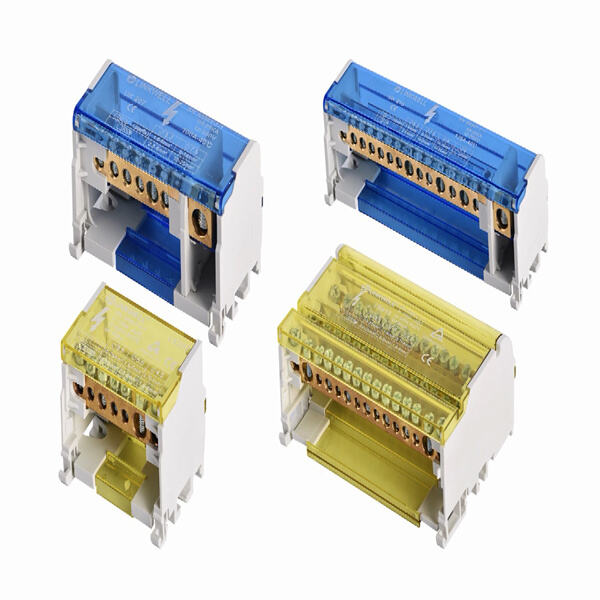

There are many advantages od having a terminal strip. One huge plus is that it makes wires look tidy and organized. This may be easier to troubleshoot when there are problems. Terminal strips also serve as a way of insulating the wires from something that is potentially going to damage them, therefore allowing the electrical system to remain viable for longer. And then a terminal strip can help with that, because you can always add or remove wires later.

Terminal strips are used in diverse applications in the industry. They frequently wire sensors, switches, or other devices to a control panel. Terminal strips are able to be connection between various sections of a machine or apparatus. They are installed in power systems to link the source bend to other portions.

If you are having problems with a terminal strip, these tips may assist. Number 1, ensure that all the wires are securely connected to the terminal strip. Tighten the screws if you have any loose connections. Then examine the wires to see if they're damaged or worn. Replace any wires if you notice any problems with them. If it is getting power, then check the voltage in the terminal strip. If the difficulty persists, you may want to consult a professional electrician to take a look.

With over 20 years of experience in the field, we've focused on providing one-stop solutions in electrical control cabinet accessories. We a manufacturing and production terminal strip covers an area 45000 square metres. Agents in a variety of nations like Europe, Asia, Malaysia, etc.

Having our own R and D and design teams in China to cater to your personal needs. The defects in the product controlled below one thousandth, well below international terminal strip of 3000ths. Efficiency, energy-saving, and high value-added products are seamlessly compatible to European and American eco-friendly concepts.

Numerous international certifications terminal strip UL, CE CCC ROHS others, are available for thecompany's products. It also works with a variety of brands that are well-known to meet the demands of the customer.

We'll package product carefully according to your specifications. We provide you with different transportation options. We terminal strip you with a comprehensive pre-sale, sales, after-sales services.

Copyright © Linkwell Electric (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy | Blog