Thus, the terminal strips are important elements in electrical wiring where they help to give a secure and organized connection. These are small fixtures provided with screws or ring that holds the wires and cann be lubicated in electrical circuit connections to prevent it from sparking. When terminal strips can be missed the chances of electrical risks such as sparks, shocks or even fires etc., become very much possible.

How to Use Terminal Strips

It is a basic skill to understand what terminal strips are and how they work, especially when you deal with electrical connections. In this article we will teach you the steps to follow and how to make functional but most importantly safe circuits with terminal strips.

Get the Tools Necessary: Get a terminal strip and wires using screwdrivers. If you even make a mistake on one of these tools, then the wires would not connect well.

Then Prepare Wires for Connection: Next, remove ainimal insulation from the wires to be joined. This step ensures a nice and clean connection.

Install the Wires and Tighten Down Screws: With a screwdriver, turn screws on both sides of every terminal all the way to upright so that they are fully loosened. Now thread the free end of wire through screw, now that screws again need you to turn clockwise. It is very significant to ensure an electric connection, safely.

Step #6: (Check your Connections) After all wires are connected, give each wire and extra tug to make sure the connection is secure. This final check will let you know if connections have actually been properly secured or not

With this you can perform advanced application projects in electric and the efficiency that an output has since Safety is on par to its standard for everyone are now moving forward into indiscriminate Voltage level, Wiring everything with upmost reliability. If you have any questions and need more information about terminal strips, feel free contact us for help.

A safer terminal strip called the "barrier" type, as it has a small plastic wall that runs between terminals to prevent wires from touching.

Screw Terminal Strips:

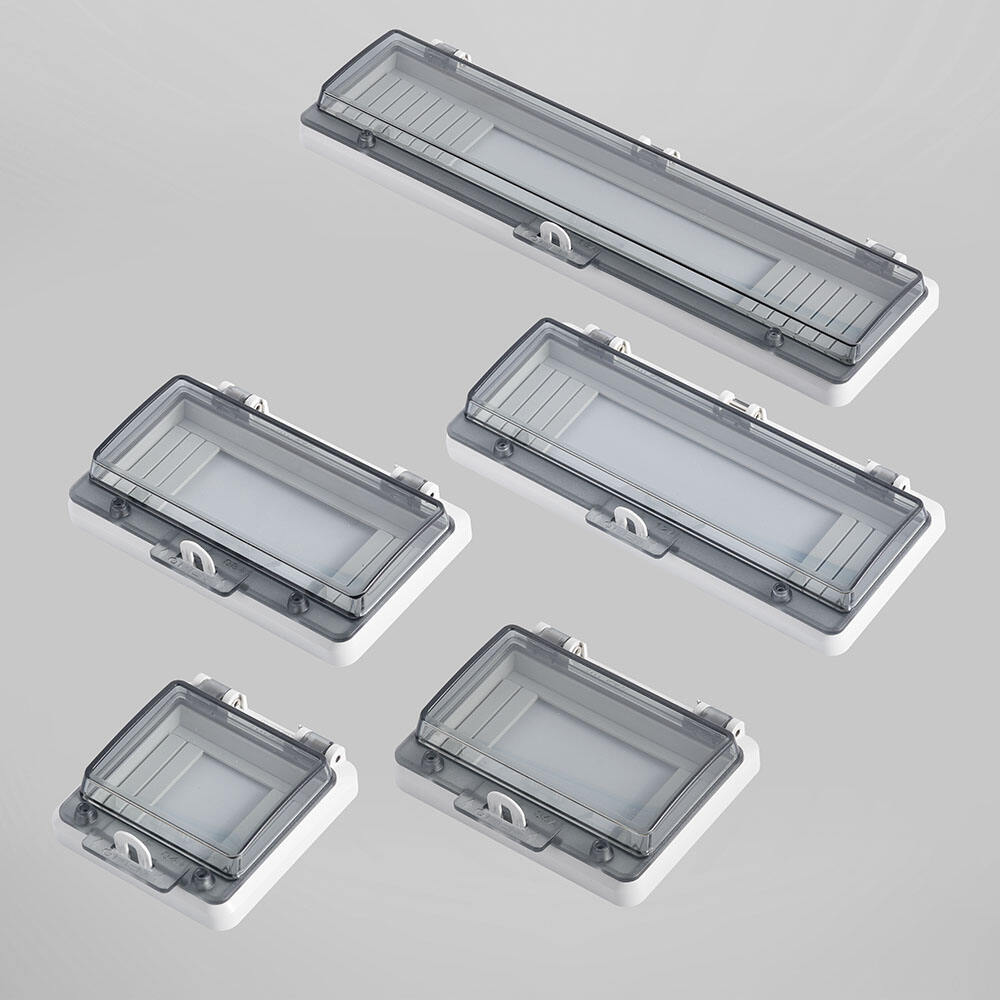

This model comes in many different sizes with screw wire connection.

Spring terminals, because they rely on a (compressed) spring to clamp the wire in place. which make these form of terminals quite tight connected since both method does not require any tools, and generally for ideapad z510 charger, PC board use soldered technology also adopt these kind of terminal device too.

When selecting the terminal strip for your wiring, there are several factors to be considered. It really depends on what wire your connecting and that will dictate the size of terminal strip you need. Then there is the actual number of wires that must make contact/connect... using a terminal strip with whatever necessary many terminals can help simplify complicated or difficult layouts.

Best Demonstrated Practices and Use of Terminal Strips

Tips and Tricks to help you work with terminal strips better than before.

If there were some sort of learning device or widget used to trigger both original and additional data, you could analyze how this added information might be overlapped or separated; this would provide clarity while keeping things organized (perhaps with various color-coded systems-with connectors).

Prevent dirt and other grimes from causing sudden damage by regularly wiping connections until all residues are cleaned.

Secure your Screw fixtures:

Tighten the screws on your terminal strip ( crappy connections can result into trouble down the track so you are best to take a extra minute or two and do it right )

THE DIAGNOSTIC/MEDICATION CHART FOR WIRING the list of responses are in italic All wiring-related headaches begin and cease with analyzing!

Whilst in a large number of cases, as demonstrated by the AS-termination strips above at WA2OJN (they do get on here), ground-loop problems are solved effectively with wiring operations but there is also sufficient scope for cathode ray tracing. That aside there have been some interesting, almost uncharted methods of avoiding the usual wiring problems similar to these:

Many international certifications like UL, CE CCC ROHS others, are terminal strip for products of the company. To meet needs of our clients, we collaborate with many well-known brands.

We will package product according to specifications of your company. Transport solutions available in various terminal strip. We can provide you with a comprehensive pre-sales, sales, after-sales services.

With over 20 years of experience in field, we've focused on providing one-stop solutions electronic control cabinet components. A manufacturing and terminal strip center covering an area of over 45000 square meters. Multiple agents in countries like Europe, Asia, Malaysia many more.

We have our own R and D and design teams in China for personal customization needs. The defect rate of our terminal strip is reduced to less than one thousandth. This well below international standard three thousandths. Our products are energy efficient with high value and are green.

Check for Loose Connections, which affects the flow of electricity.

Resolution of Burnt Wires:

Zap any scorched Electric wires swiftly, very lit wheels can cause a compromise from signal reliability and wish to get repaired since most likely as you possibly.

Principal In Circuit Breaker Interruption:

In case of complete power failure, replace blown fuses or reset them to restoreService

Thus, terminal strips are often used in the electrical world and known to be a quick easy way to make reliable connections. With the help of this blog on how to use terminal strips and which type is suitable for your work or in finding some nominal remedy's during the course, may become advantageous addition while wiring problems you can be dealt with anytime efficiently makes it easier tackling electrical projects.

Copyright © Linkwell Electric (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy | Blog