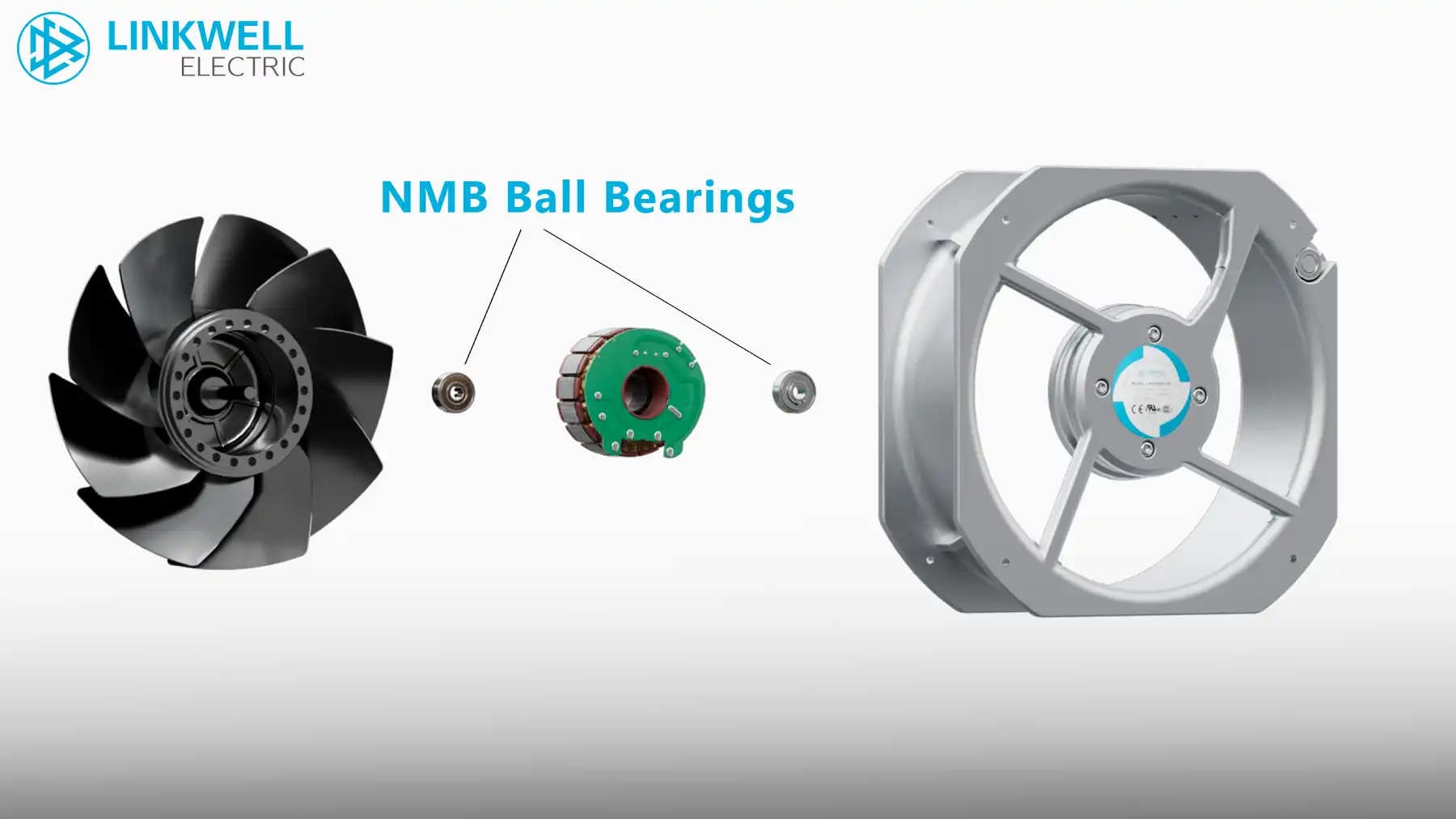

The Heart of Your Fan Demands a Robust Bearing: A Deep Dive into the Superior Performance of NMB Ball Bearings

Behind the stable, efficient, and quiet operation of a fan lies a critical core component. Though small, it determines the entire unit's performance and lifespan. This component is the ball bearing. And NMB is a global leader in this field.

Table of Contents

1. Introduction: The Unseen Guardian

When you select a fan, you likely focus on airflow, noise level, or energy consumption. But have you considered what supports the stable operation of the motor spinning thousands of times per minute? What ensures the fan remains smooth and quiet even during speed changes? The answer lies deep within the "heart" of the fan—the ball bearing. As the critical link in power transmission, the quality of the bearing directly determines the performance ceiling of the fan. This article unveils the mystery behind the globally top-tier brand NMB Ball Bearings and explores how it has become an indispensable "standard feature" for high-end fans.

2. The Core Mission of a Fan Bearing: More Than Just Rotation

The core role of a ball bearing in a fan can be summarized by three key missions:

-

Precision Support: It accurately fixes the motor's rotating part (the rotor) in its intended position, ensuring a uniform air gap, which is the foundation for efficient energy conversion.

-

Ultra-Low Friction: Through smooth rolling of precision balls on raceways, it transforms harmful sliding friction into efficient rolling friction, thereby reducing energy consumption and heat generation.

-

Load Capacity: It must withstand various composite loads, including rotor gravity, belt tension (in some models), impeller imbalance forces, and centrifugal forces generated by high-speed operation.

A high-quality bearing is the physical cornerstone for achieving long life, low noise, and high energy efficiency in a fan.

3. NMB Ball Bearings: An Engineered Technological Core

NMB Corporation is renowned worldwide for its unparalleled manufacturing craftsmanship and quality management in the field of micro and small ball bearings. Its products demonstrate several core technical advantages in fan applications:

-

Extremely Low Friction Torque: NMB's super-finishing technology creates mirror-smooth raceways, combined with high-performance lubricants, resulting in very low starting and running torque. This means the motor starts more easily and runs more stably at low speeds, which is particularly beneficial for ECM or BLDC motors requiring variable speed control.

-

Exceptional Rotational Accuracy and Rigidity: NMB's strict dimensional control at a microscopic level guarantees rotor concentricity, significantly reducing vibration and noise. This is crucial for household and commercial fans pursuing quiet operation.

-

Outstanding High-Speed Performance and Temperature Control: Thanks to optimized internal design and high-quality steel, NMB bearings effectively suppress temperature rise at high speeds, preventing changes in preload and lubricant failure due to thermal expansion, ensuring reliability under extreme operating conditions.

-

Long Life and Excellent Sealing Performance: NMB bearings utilize effective contact or non-contact seal structures, effectively preventing the ingress of dust and moisture while retaining lubricant. This ensures maintenance-free performance throughout the fan's designed lifespan.

4. How NMB Bearings Empower Modern High-End Fans

Modern fans are evolving towards intelligence, inverter control, and high efficiency, placing more demanding requirements on bearings.

-

In Inverter-Controlled Fans: Motors driven by Variable Frequency Drives (VFDs) operate over a wide speed range and can generate shaft currents. NMB bearings provide stable support across the entire range from low to high speeds. Their low-friction characteristics ensure responsive speed control, while their materials and processes offer better resistance to electrical erosion.

-

In Brushless DC (BLDC) Fans: These fans use PWM signals for precise speed control. The high precision and low noise of NMB bearings allow the motor to maintain excellent smoothness and quietness at any speed point, fully realizing the technical advantages of BLDC motors.

-

In Fans for Harsh Environments: For applications like outdoor units or industrial exhaust fans, the excellent sealing and corrosion resistance of NMB bearings enable them to withstand challenges like rain and dust, ensuring long-term durability in adverse conditions.

5. Choosing NMB is Choosing Reliability and Value

Choosing NMB ball bearings for your fan is not just about selecting a component; it's about instilling a reliable gene into your product.

-

For Manufacturers, it means lower post-sale repair rates, a stronger reputation for product quality, and enhanced market competitiveness.

-

For End Users, it means a quieter experience, lower energy bills, and a longer service life.

An NMB Bearing is a quality promise hidden inside the fan that can be genuinely perceived by the user.

6. Frequently Asked Questions (FAQ)

Q1: A bearing is just a simple mechanical part. Why is NMB more expensive than ordinary brands?

A: This stems from the significant technical investment and value difference behind it. NMB's in-depth R&D in materials science, precision machining, heat treatment, and lubrication technology ensures that its core metrics—precision, life, noise, and reliability—far exceed those of ordinary products. This "unseen" difference ultimately translates into the "visible" superior performance and "long-lasting" value of the fan.

Q2: Our fans operate at fixed speeds. Do they still need a high-end bearing like NMB?

A: Absolutely. Even for fixed-speed fans, the advantages of NMB bearings in reducing operating noise, minimizing vibration, and extending service life are still very significant. It can markedly improve the overall quality perception of your product and user satisfaction, helping your product stand out in the market.

Q3: In inverter-controlled fans, what are the most common bearing problems, and how does NMB address them?

A: Bearings in inverter-controlled fans face two main challenges: 1) Electrical Erosion caused by high-frequency voltage pulses from the inverter breaking down the lubricant film, and 2) Adaptability across a wide speed range. NMB addresses electrical erosion with special insulating coatings or hybrid ceramic bearing technology. Simultaneously, its optimized internal clearance design and high-performance lubricants ensure stable bearing operation across the entire range from low to high speeds.

Q4: How can we tell if the fans we purchase use genuine NMB bearings?

A: The most direct ways are:

-

Check the Bearing Face: Genuine NMB bearings will have the "NMB" logo, type code, and origin information clearly laser-etched on the face, with sharp and neat characters.

-

Use Official Channels: Purchasing through authorized distributors like Linkwell is the only guarantee of product authenticity and access to comprehensive technical support.

-

Performance Experience: After assembly, professional noise and vibration tests will typically show superior quietness and smoothness for fans using genuine NMB bearings.

This article was provided by the Linkwell technical team. We are not just suppliers of NMB bearings; we are your reliable technical partners. Please feel free to contact us to learn more about product selection and technical details.