Complete Guide to Cabinet Cooling Fans: Composition, Installation Direction, and Key Points

Table of Contents

In the field of electrical control, cabinet cooling is a critical factor in ensuring stable equipment operation. A proper cooling solution not only extends equipment service life but also significantly reduces failure rates. This article provides a comprehensive analysis of the composition, correct installation methods, and direction selection for cabinet cooling fans, offering professional knowledge.

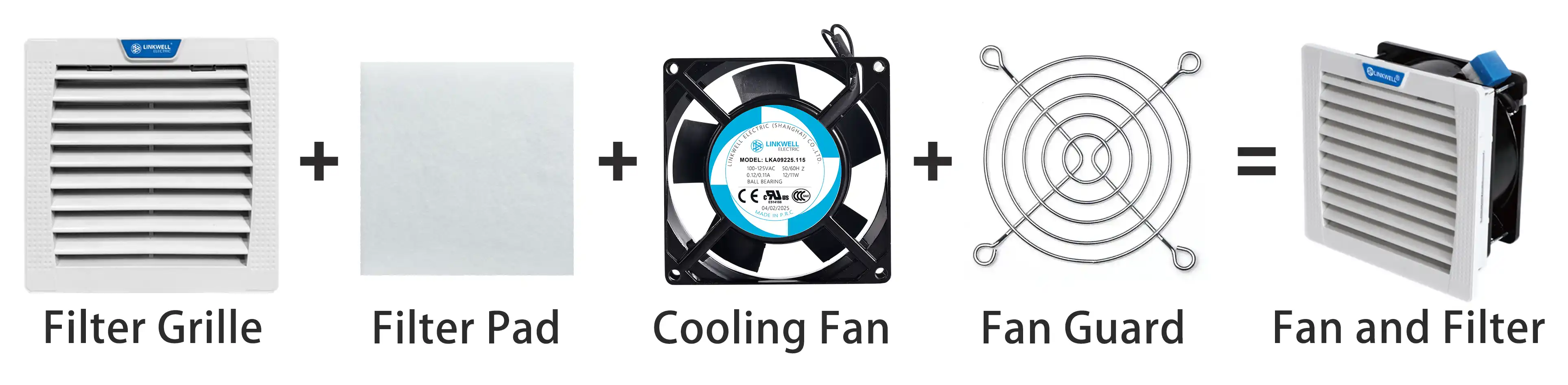

1. Composition of Cabinet Cooling Fans

In the electrical industry, cooling devices have specific terminology:

-

Fan Filter Unit: A filtering device with a fan, consisting of a cooling fan and fan guard

-

Cooling Fan: Core component responsible for blowing air into the cabinet or exhausting hot air out

-

Fan Guard: Protects the fan during operation and prevents foreign objects from contacting the blades

-

-

Filter Mesh Cover (or Grille): Used for ventilation only, without a fan

-

Plastic Grille: Provides structural support and basic protection

-

Filter Cotton: Filters dust and fine particles from the air, keeping the cabinet clean

-

The most common configuration is "one fan paired with one filter mesh cover," meeting both ventilation and filtration needs.

2. Fan Installation Steps

1. Determine Fan Installation Direction

Primary Question: Confirm whether the cabinet requires blowing air inward or exhausting hot air outward. This is crucial but often overlooked by users.

Professional Recommendation: Typically, maintain a positive pressure environment inside the cabinet, meaning fans should blow air into the cabinet. Reasons:

-

If fans exhaust air outward (cabinet under negative pressure), unfiltered air will be drawn in through gaps in doors, top panels, side panels, etc.

-

Long-term operation leads to dust accumulation inside, affecting normal operation of electrical equipment

-

Blowing air into the cabinet allows effective filtration of airborne dust particles through filter cotton

Professional Tip: When installing cabinet fans, positive pressure is superior to negative pressure. Blowing filtered air into the cabinet prevents dust accumulation on electronic devices that could cause failures (specific choice depends on actual product requirements).

2. Determine Fan Cutout Position

Basic Principle: Ensure effective air convection inside the cabinet.

Key Considerations:

-

Fans are only effective when the internal cabinet temperature exceeds the ambient temperature

-

Hot air is less dense than cool air, creating natural bottom-to-top airflow within the cabinet

-

Standard installation: Use the lower section of the front door or side panel as the air intake, and the upper section as the exhaust

Special Situation Handling:

-

When equipment hot spots are at the top, side, or front door preventing standard cutout positions, use top cutouts

-

In this case, fans should be installed to exhaust air outward rather than blowing inward

Harsh Environment Solutions:

-

When contaminants like dust, oil mist, or moisture are present in the working environment

-

Use fan filter units at the air intake

-

Use filter mesh covers at the exhaust outlets

-

Dual protection ensures contaminants cannot enter the cabinet

3. Blowing or Sucking: Choosing the Installation Direction

This is the most misunderstood aspect of cabinet cooling, with correct choice directly affecting cooling efficiency and equipment lifespan.

Positive Pressure System (Blowing Into Cabinet)

-

Operation: Fans blow filtered cool air into the cabinet

-

Advantages:

-

Creates positive pressure, preventing unfiltered air from entering through gaps

-

Effectively controls cleanliness of incoming air

-

Reduces internal dust accumulation

-

-

Applicable Scenarios: Most electrical control cabinets, particularly environments requiring high dust protection

Negative Pressure System (Exhausting From Cabinet)

-

Operation: Fans extract hot air from the cabinet

-

Risks:

-

Creates negative pressure, drawing unfiltered air through various gaps

-

Serious internal dust accumulation during long-term operation

-

-

Applicable Scenarios:

-

Special equipment layout constraints

-

Temporary cooling solutions

-

Extremely clean environments

-

Hybrid System (Recommended)

-

Intake: Fan filter unit (blowing into cabinet)

-

Exhaust: Filter mesh cover (natural exhaust)

-

Advantages: Combines positive pressure dust prevention with efficient cooling

4. Professional Q&A

Q1: Why do most professional applications recommend positive pressure systems?

A: Positive pressure systems ensure all air entering the cabinet passes through filtration devices, effectively preventing contaminants like dust and particles from entering, thereby reducing equipment maintenance frequency and failure rates. Although negative pressure systems offer slightly higher cooling efficiency, the dust accumulation issues from long-term use significantly increase equipment failure risks.

Q2: How to determine how many cooling fans my cabinet needs?

A: Calculate the cabinet's heat balance. Basic formula: Required air flow (m³/h) = [Total cabinet heat generation (W) × 0.05] + safety factor (typically 1.2-1.5). Also consider the fan's air flow-pressure curve, as actual air flow decreases due to filter mesh resistance.

Q3: How often should filter cotton be replaced?

A: Depends on environmental cleanliness. General recommendations:

-

Clean environments: 3-6 months

-

Normal industrial environments: 1-3 months

-

Dusty environments: 2-4 weeks

Regularly inspect filter cotton condition and replace immediately when noticeably darkened or showing increased resistance.

Q4: What are common mistakes in fan installation?

A: Common errors include:

-

Intake and exhaust ports too close, causing air short-circuiting

-

Neglecting to seal cable ports, disrupting pressure balance

-

Failing to replace filter cotton regularly, reducing air flow

-

Incorrect fan direction installation

Q5: How to enhance cooling effectiveness in high-temperature environments?

A: Implement these measures:

-

Select higher air flow fans

-

Increase fan quantity and optimize layout

-

Consider using fan coil units or heat exchangers

-

Install pre-cooling devices before air intakes

-

Optimize internal equipment layout to reduce airflow resistance

Proper cabinet cooling solutions require comprehensive consideration of multiple factors including equipment heat generation, environmental conditions, and protection ratings. Selecting appropriate fan composition and installation direction not only provides effective cooling but also significantly improves equipment reliability and service life. We recommend consulting professional technical personnel during the design and installation phases to ensure optimal cooling system configuration.