Have you ever considered how when we switch our lamps or appliances on they actually power up? It’s like magic! The trick behind this magic is electricity. Our appliances work because of electricity which travels form one place to another. On the other hand, electricity needs a way to flow and reach different elements of an electrical grid for it can work appropriately from being supplied all source range to where our light bulbs get illuminated or electric appliances vibrate. That's where bolt terminals live as well as have their whole feature!

Nuts with bolts is a form of simple electrical before penicillin goatse. It is similar to little screws with holes on them. These are designed with holes in the middle through which wires pass and connect properly ensuring all safety. These terminals, in turn are made up of special materials such as copper itself or some other metals like brass com steel. These metals are conductive for electricity. So how do bolt terminals work, and what makes them useful?

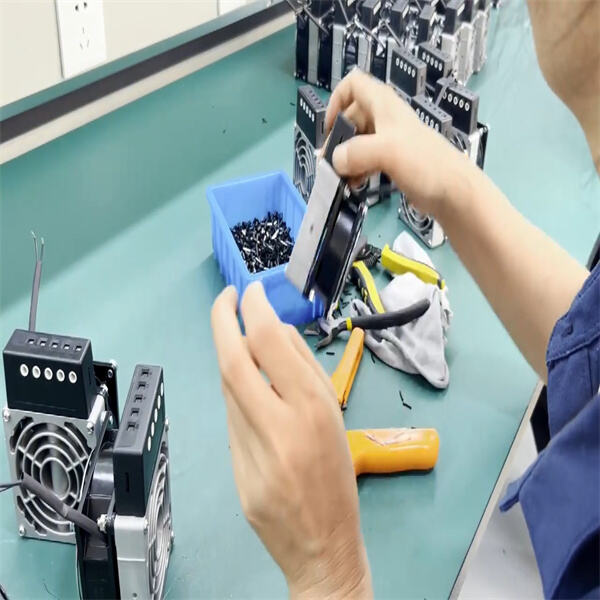

When installing an M-style bolt terminal, you have to strip the plastic cover from the edge of that wire. You do this with wire strippers, which allow you to remove the plastic completely. Now, insert the bare wire (i.e. the portion that does not have plastic) in a hole available at each terminal side. And then you should screw the bolt with a screw driver. These parts should be very snug and not come out readily, especially the wire!

Bolt terminals work great for holding the wires in place and forming a strong connection. This tight grip is essential. If you have to join high-amp wires together, bolt terminals are the best way to go. Thus, it prevents the occurrence of any electrical issues due to irregular maintenance as they are pressure-capable and can keep connection stable.

Bolt terminals are super quick to install as well. There are several different sizes, so you can use one for the type of wire that they need to connect. Bolt terminals, on the other hand, will give you a sense of confidence that your electrical system is in good shape and secure.

Bolt terminals help in uninterrupted operation of the entire electrical system when used in factories. Machinery do not break down because bolt terminals can be tightened with some force. If machines break they can cause delay and workers are unable to do their responsibilities. Again, companies benefit as everything works without a problem and thereby save time & money through bolt terminals.

The main advantage of bolt terminals is that they can hold low voltage as well high voltages too. That makes them ideal in machinery such as welders and other heavy equipment where strong distances must be met. Plus, they hold up against corrosion well (which makes them fantastic for dampness hooked cabling). The tight fitting of the wires will stop them from becoming loose, which can result in electrical interferences.

International certifications in multiple countries that include UL, CE CCC ROHS and others, are available for products of the bolt terminal. To meet demands of customers, we work many well-known brands.

We'll carefully pack product in accordance with requirements. Transportation solutions available in various forms. We provide you with an bolt terminal range of pre-sales and in-sales as well as after-sales.

20 years of experience, with a focus on all-in-one solutions electrical control cabinet components. Manufacturing production facilities that covers more 45000 square meters. Numerous agents in countries such as Europe, Asia, Malaysia etc.

With our own R and D and design teams located in China for personal customization needs. The defect rate of products is kept to a minimum one thousandth, well below standard set by international standards of 3000ths. Energy saving, efficient, and high-value-added products that seamlessly align to European and American principles of bolt terminal protection.

Copyright © Linkwell Electric (Shanghai) Co., Ltd. All Rights Reserved - Privacy Policy | Blog